Water Treatment

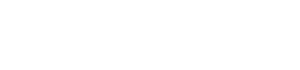

The Belgium-based company Ekopak develops customized water treatment equipment. The company ships industrial process water purification systems in standard shipping containers all over the world. These containers contain e.g. reverse osmosis or ultrafiltration units and deliver process water for steam, water for breweries, etc. They are mainly used to supply water for food, medical, textile and industrial plants. The input is mostly water from a nearby river.

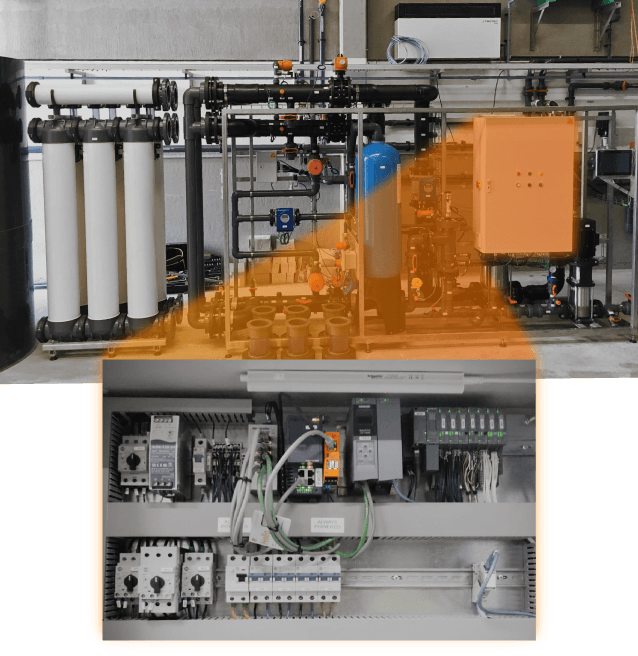

The water treatment installations are controlled by a Siemens S7-1200/1500 PLC. To get important data out of the system and into the cloud, a RevPi Core is used. Factry, a Belgian software company, preinstalls a RevPi Core module with its OPC-UA collector and sends it to Ekopak. Ekopak then plugs in the RevPi in the control box and powers it on during commissioning of the process water purification system. The unit is preconfigured to contact Factry’s cloud backend and request its configuration. The RevPis are collecting up to 500 tags/measurements per second and transmit these over a 4G connection to Factry’s cloud infrastructure.

Once the data is there, Grafana dashboards help Ekopak get new insights into their process. It is used for monitoring, alerting and problem solving. The business outcome is manyfold.

- Reliable process data collection

- Alarming & events arrive in real-time

- Beautiful trending of measurements with Grafana

- And all of this with an open source/100% open software stack

Factry is a strong believer of the open source culture. They`ve been sharing their developments with the community since their founding in 2016. Read more on factry.io.

Module used

RevPi Core