RevPi Compact

Product Description

The RevPi Compact is an open source compact controller for IIoT and automation projects based on the Raspberry Pi Compute Module 3+. The RevPi is a non-modular base module from the Revolution Pi family. Due to its flat design, the RevPi Compact is suitable for installation in sub-distribution cabinets in accordance with DIN EN 18012.

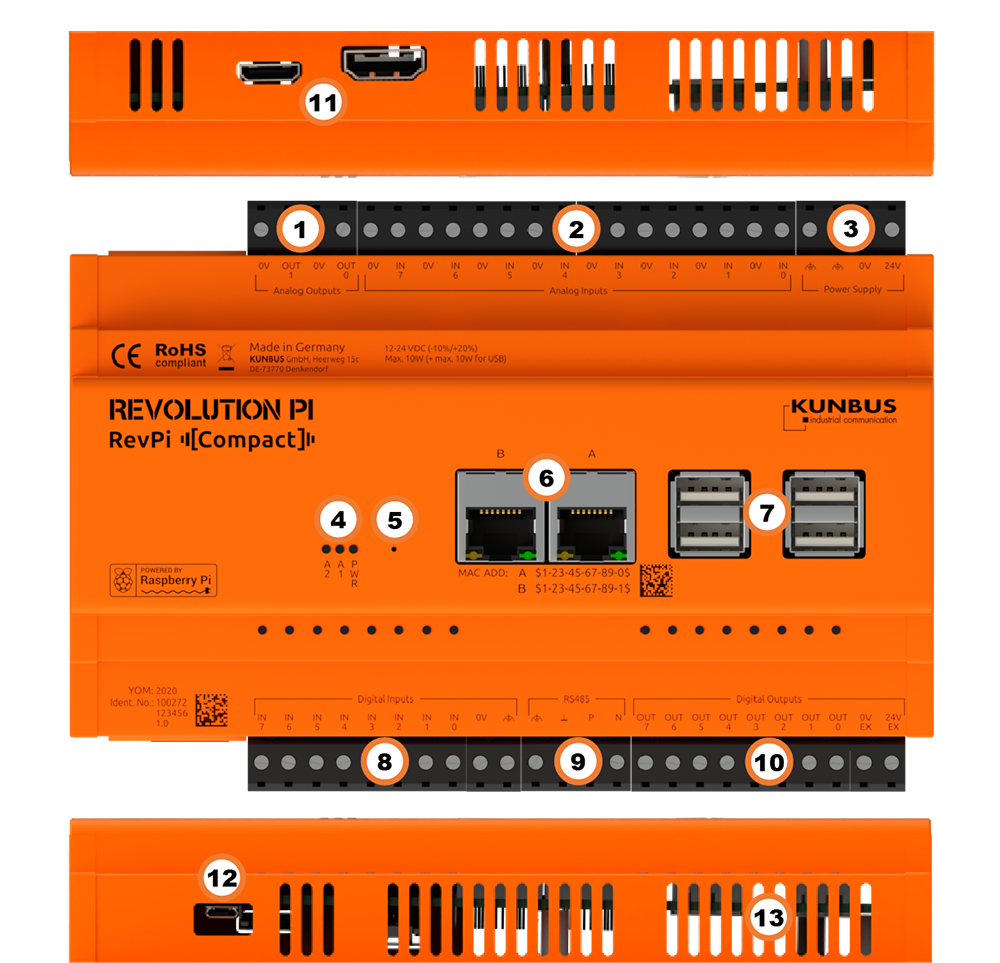

Components

| Position | Component | Application |

|---|---|---|

| 1 | 2 × analog output (4-pin plug) | Analog Inputs and Outputs |

| 2 | 8 × analog input (16-pin plug) | Analog Inputs and Outputs |

| 3 | Power Supply (4-pin plug) | Connecting the Power Supply |

| 4 | 3 × status LED | LEDs |

| 5 | Reset button | Reset Button |

| 6 | 2 × RJ45 Ethernet | Ethernet Interfaces Establishing a Network Connection |

| 7 | 4 × USB A | USB Interfaces |

| 8 | 8 × digital input (10-pin plug) | Digital Inputs and Outputs |

| 9 | 2 × RS485 (4-pin plug) | Serial Devices (RS485) |

| 10 | 8 × digital output (10-pin plug) | Digital Inputs and Outputs |

| 11 | HDMI Micro HDMI | Set up Desktop Mode |

| 12 | Micro USB | Saving and Reinstalling the Image |

| 13 | Ventilation Slots | Mounting the Device on a DIN Rail |

Compatible RevPi Image

- RevPi Bookworm Image

- RevPi Bullseye Image

- RevPi Buster Image

- RevPi Stretch Image

See: RevPi Images.

Virtual Devices

The Virtual Devices are delivered with the RevPi image as components in PiCtory included:

Scope of Delivery

The scope of delivery includes

- RevPi Compact (non-modular base module)

- 4-pin plug Power Supply

- 4-pin connector Analog Outputs

- 4-pin plug RS485

- 10-pin connector Digital Inputs

- 10-pin connector Digital Outputs

- 16-pin connector Analog Inputs

- Supplement

Mounting and Connecting

The RevPi was developed for use in a control cabinet. Observe the specifications for the Intended Use and all Safety Instructions.

Danger to life due to electric shock

There is a risk of fatal electric shock when working on devices in the switch cabinet with 230 V mains voltage.

▷ Work in the switch cabinet may only be carried out by qualified electricians.

▷ Before carrying out any work in the switch cabinet, switch off the power supply properly.

Carry out the installation and connection in the following order :

-

Mount your RevPi on a DIN rail.

-

Connect all other devices such as sensors and actuators. The interfaces available to you for this can be found in the Components section.

-

Connect a monitor and a keyboard if you want to operate the RevPi in Desktop Mode. This is not necessary if you can access the RevPi via a network connection.

-

As the last step connect the power supply .

The digital outputs must be supplied with voltage separately via the 0V EX and 24V EX connections.

Access to the Device

The RevPi is accessed in two steps:

Install all available Updates as soon as the RevPi is connected to the internet, so that the system is always up to date with security-relevant features.

Alternatively, access is possible without a network, see Desktop Mode.

See also:

Reset Button

The reset button restarts the RevPi.

▷ You can press the button by means of a thin object (e.g. a needle).

❯❯ The RevPi shuts down and restarts.

Configuration

Basic Configuration

From the RevPi Bookworm image (10/2024) onwards, the basic configuration of the RevPi devices is carried out via the Cockpit web application.

Until the RevPi Bullseye Image (04/2024), the basic configuration of the RevPi devices is carried out via the RevPi Status web application.

Configuring the Base Module in PiCtory

▷ Start PiCtory.

▷ Select the RevPi base module from the Device Catalog and drag and drop it onto the empty slot with position number 0.

❯ The configurable values appear in the Value Editor.

▷ Save the configuration as the start configuration with File > Safe as Start-Config.

❯❯ The start configuration is called up directly after each boot process.

Configuring PiCtory Device Data

▷ Under Device Data, select a bit-wise or byte-wise data schema for the inputs and outputs:

- 15 or 22 inputs

- 4 or 11 outputs

The number of inputs and outputs in the Value Editor and their units (BOOL or BYTE) change accordingly.

Input Values

| Value | Function |

|---|---|

| INP Core_Temperature | CPU Temperature |

| INP Core_Frequency | CPU Frequency |

| INP Din (BYTE) INP DInBit_1 ... 8 (BOOL) | Input values of the digital inputs |

| INP AIn_1 … 8 | Input values of the analog inputs |

| INP DIn_Status | Status of the digital inputs |

| INP DOut_Status | Status of the digital outputs |

| INP AIn_Status | Status of the ananlog inputs |

| INP AOut_Status | Status of the ananlog outputs |

Output Values

| Value | Function |

|---|---|

| OUT RevPiLED | Status byte for LEDs |

| OUT DOut (BYTE) OUT DOutBit_1 ... 8 (BOOL) | Output values for digital outputs, depending on the selected data schema |

| OUT AOut_1 ... 2 (INT) | Output values for analog outputs |

Memory Values

| Value | Function |

|---|---|

| MEM InputDebounce | Debounce filter for all inputs: |

| MEM AInMode_1 … 8 | Mode for the respective analog input: |

Serial Devices (RS485)

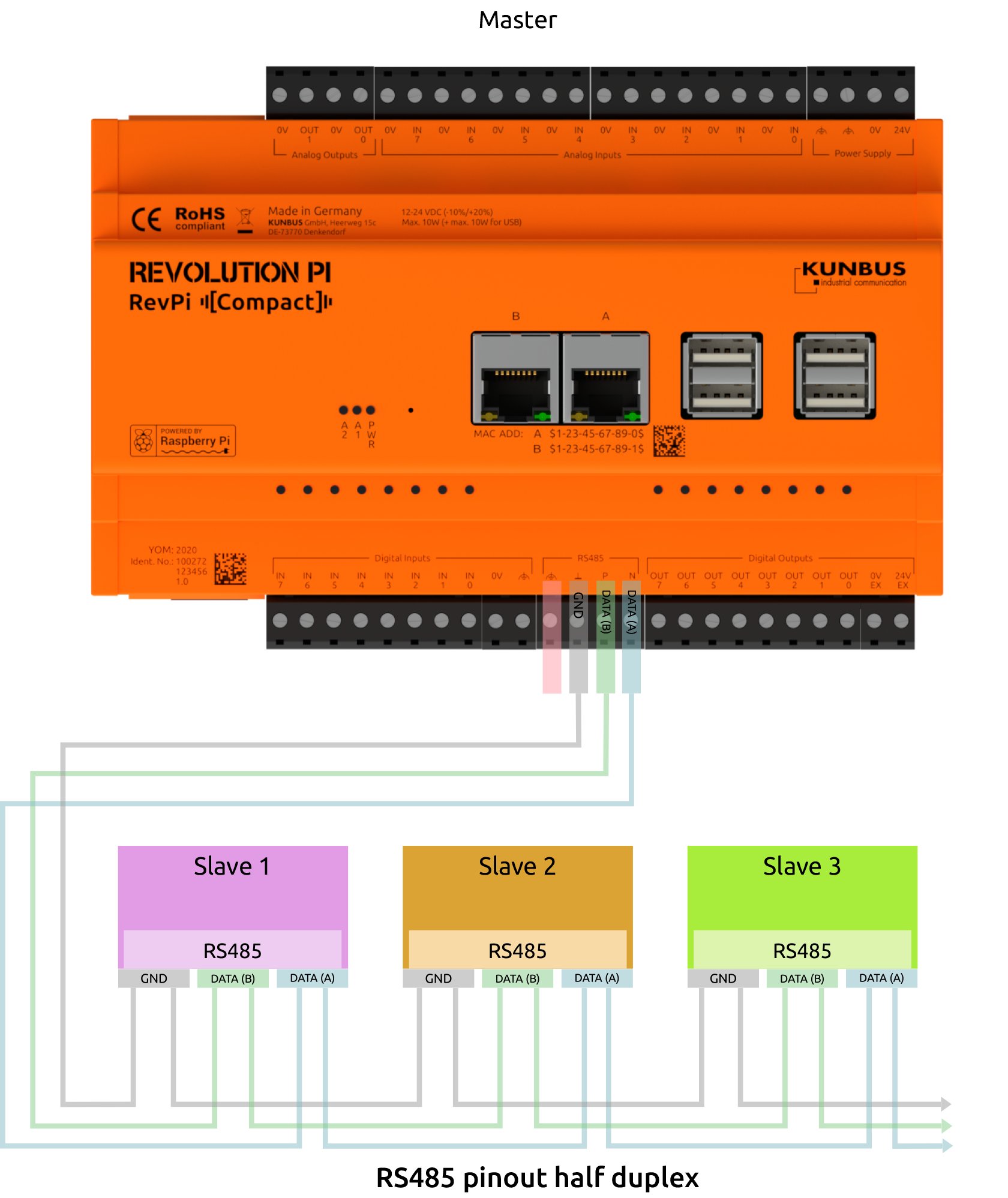

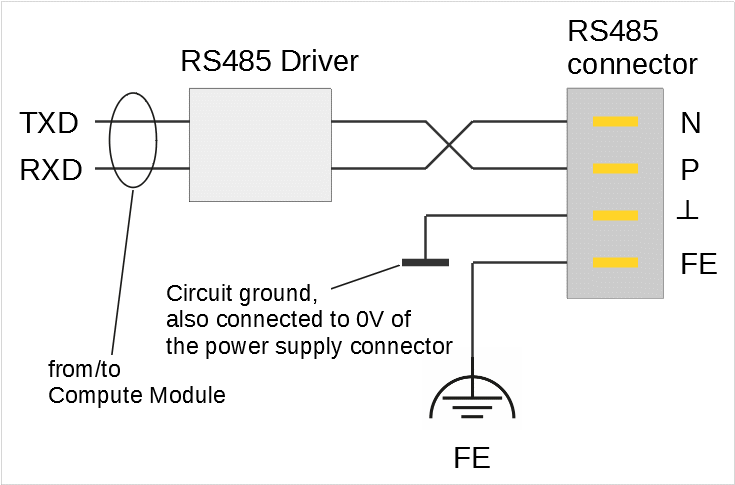

The RevPi has an RS485 interface to connect serial devices such as sensors.

The data lines of the RS485 socket are marked P (positive) and N (negative). For other devices, these lines are often referred to as D+ and D- or A and B.

Wiring of the RS485 terminal:

Only the lines N and P are required for the actual data transmission. We recommend to use a twisted pair for longer line lengths or higher bit rates.

If a reference potential should be necessary, you can use the electrical circuit ground at terminal "┴" for this purpose. However, you should not use this connection if it is not actually necessary. The cable shielding should ideally be connected to the FE terminal.

Cables having a length >30 m and cables leaving the building must be shielded. To improve the EMC properties of the shield, connect the shield to the grounded mounting plate over a large area using a conductive cable clamp. As an alternative, you can use a conductive EMC cable gland to lead the cable through the control cabinet wall.

Linux addresses the interface via the character device "/dev/ttyRS485". You can configure bit rates up to 3,000,000. However, occasional reception errors may occur at more than 230,400 bps. The reason is that the UART of the Raspberry Pi, to which the interface is connected, has only a 16 byte FIFO and does not support DMA. The higher the bit rate, the more often the FIFO is not read out fast enough and received data is lost. For example, at 460,800 bps are 1- 2 errors per 50 MByte received, at 921,600 bps there are about 10 errors. If your RevPi Compact mainly sends data and only rarely receives it, you can also use higher bit rates. Otherwise we recommend to not set more than 230,400 bit/s.

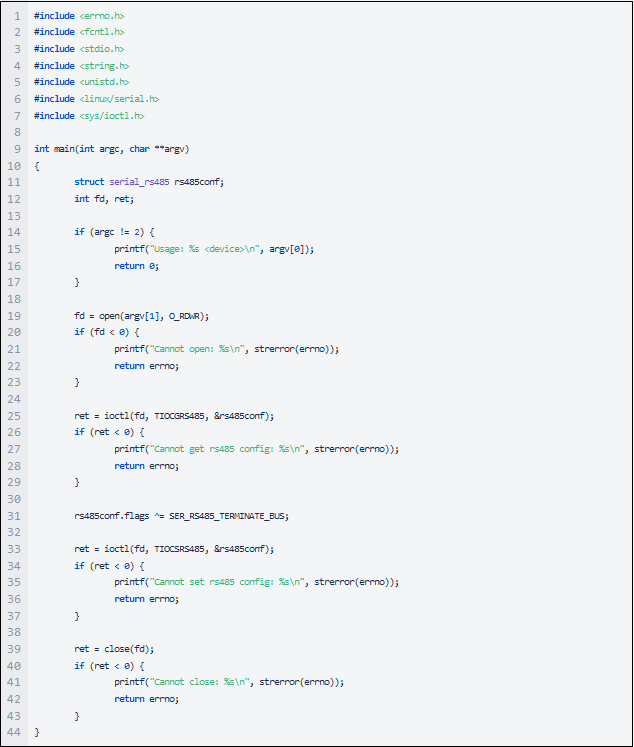

The interface has an integrated 120 Ohm terminating resistor. This termination is switched off after booting. This is the safest method, because if several devices on the RS485 bus switch on their termination, no communication is possible at all. Short cables allow for communication also without termination. For longer distances you should switch the termination on if your RevPi Compact is at the end of the bus.

Switch the termination on and off as follows:

▷ Open the character device "/dev/ttyRS485" with open().

▷ Read out the current RS485 configuration by a TIOCGRS485 ioctl()

▷ Set or delete the SER_RS485_TERMINATE_BUS flag in the "struct serial_rs485".

▷ Activate the changed RS485 configuration by a TIOCSRS485 ioctl().

▷ Close the character device by close().

You have to repeat these steps after each boot if you want to enable termination. We have prepared a C-listing including these steps that you just need to compile:

Ethernet Interfaces

The RevPi has two Ethernet Interfaces. Each of the two sockets is designed for different requirements.

Ethernet Interface A

You can achieve a maximum throughput of 11.2 MByte/s at this interface.

This Ethernet interface is connected to the internal USB bus. It has a maximum bandwidth of 480 MBit/s. Since all devices on the bus share this bandwidth, the throughput on this Ethernet interface may decrease if you connect many USB devices. You can address this interface in the software as eth0.

The MAC address for this Ethernet interface is printed on the housing and stored in the file "/boot/config.txt". You can change the MAC address for eth0 here, if necessary. If no MAC address is entered in the file "/boot/config.txt", e.g. because you have uploaded a new image, a unique MAC address is calculated from the serial number of the Compute Module.

Ethernet Interface B

This Ethernet interface is connected to the SPI bus (spi0). As a result, this interface shares the bandwidth with other devices you connect to the SPI bus.

You can achieve a throughput of up to 2.1 MByte/s at this interface. Even though this is slower than the Ethernet interface A, the Ethernet interface B is considerably robust against electromagnetic interference.

Please check if this interface is fast enough for your project. If you need a faster Ethernet connection for your project, we recommend to use interface A or combining both interfaces. This is explained in the following section.

You can address this interface in the software as eth1.

The MAC address for this Ethernet interface is printed on the housing and stored in the file "/boot/config.txt". You can change the MAC address for the Ethernet interface B (eth1) here, if necessary. In addition, the MAC address is stored in a separate memory module of the Ethernet interface B (eth1). This factory MAC address is used if no MAC address is entered in the file "/boot/config.txt", e.g. because you have installed a new image.

Combine Interfaces

To take advantage of both Ethernet interfaces, you can combine them into a virtual unit. It is called "bonding." This allows to use the high bandwidth of the Ethernet interface A (eth0). In case of malfunctions on the USB bus, the system switches over automatically to the robust SPI interface.

Details about combining the two Ethernet interfaces are provided here.

Please note that it is not easy to connect both Ethernet interfaces to the same subnet without bonding. If you want to proceed in this way, you need to adjust the ARP configuration and it requires policy routing. However, since this is very complex, we do not recommend this method.

Analog Inputs and Outputs

The RevPi Compact has eight analog inputs and two analog outputs.

Analog Inputs

You can measure a voltage between 0 and 10 V with each of the analog inputs or do a RTD measurement using a resistance temperature sensor (Pt100/1000). The analog input can also act as a constant current source. The Pt100/1000 sensor is connected directly to the analog input. Only a two-wire measurement can be made.

The MCP3550-50 analog-to-digital converter used for this purpose has a high resolution of 21 bits, but takes 85 milliseconds per measurement which is a comparatively long time. Another 40 milliseconds are required for switching the constant current source on and off and for switching the multiplexer, via which the eight inputs are connected to the ADC.

You can access the analog inputs either by using or not using piControl:

Using piControl, each input is read out with a cycle time of one second and stored in the process image as a 16-bit value in mV (for voltage measurement) or in 1/10 °C (for temperature measurement). Whether an input is used for voltage or temperature measurement is selected in PiCtory.

If piControl is not used, the cycle time for reading a single input is reduced to 125 milliseconds, and the raw value is available in full 21-bit resolution. You can calculate the values from this raw data.

Analog Outputs

Your RevPi Compact has two analog outputs. They can output a voltage between 0 and 10 V. You can connect actuators such as frequency converters.

The DAC082S085 digital/analog converter used for this purpose has a resolution of 8 bits.

Similar to the analog inputs, you can access the outputs either by using or not using piControl: Using piControl the outputs are updated by the process image with a cycle time of 250 µs. You only have to store the required voltage in mV there. Not using piControl you can update the outputs at any time. However, you have to calculate then the raw value in 8-bit resolution from the required voltage yourself.

There are three options for powering down the analog outputs: terminated with 2.5 kΩ, with 100 kΩ or high impedance. The powerdown can only be used for both outputs together and only by not using piControl.

Digital Inputs and Outputs

The RevPi has eight digital inputs and eight digital outputs.

You can access them either with piControl or without piControl. With piControl they are synchronized cyclically with the process image every 250 µs.

Digital Inputs

The digital 24 V inputs are supposed to forward signals to the controller that are e. g. determined by a sensor.

The inputs are designed for voltages up to 36 V.

- The switching threshold up to which low is guaranteed to be measured is 7 V.

- High is guaranteed from 10.2 V.

The inputs are not isolated galvanically. A separate terminal is available for connecting the ground.

The LEDs above each digital input light up if the input is high.

Debouncing can be carried out in four stages: 25 µs, 750 µs, 3000 µs or no debouncing. The debouncing can only be set jointly for all eight inputs.

The inputs are able to detect an excess temperature (135°C): a warning is then issued in the kernel log and a status bit is set in the piControl process image.

Digital Outputs

Unlike the inputs, the eight digital 24 V outputs are isolated galvanically .

The digital outputs must be supplied separately with a voltage of 12 ... 36 V via the 0V EX and 24V EX connections. Always use the same ground potential that supplies the connected sensors or actuators.

The digital outputs are protected by an automatic switch-off in case of excess temperature. This switch-off applies separately to each individual output.

The LEDs above each digital input light up if the output value is high.

The outputs are monitored by a watchdog and set to low if they are not rewritten every 9 ms. This ensures that the outputs are brought into a safe state, for example in the event of a system crash. In this case the LEDs do not light up any longer. However, this monitoring only works if the outputs are not set with piTest or piControl, but the GPIOs are written directly. The background is that the output in piControl is held at 1 by a loop until the output is actively set to 0.

USB Interfaces

The RevPi has 4 USB-A interfaces. This allows USB 2.0 client devices such as USB hard disks, surf sticks, keyboards or mice to be connected.

- The inner sockets (4a) may be loaded with a maximum of 1 A each.

- The outer sockets (4b) may be loaded with a maximum of 500 mA each.

- The total load for all 4 USB interfaces must not exceed 2 A.

If more than four USB-A ports are required, a USB hub can be connected.

LEDs

LED PWR

The PWR (Power) LED indicates the device status.

| Signal | Function |

|---|---|

| Green | Power supply is connected. |

| Red | There is a communication fault between connected modules. |

LED A1 and A2

LEDs A1 and A2 are customizable.

The LEDs can be used for user-specific requirements such as indicating a network connection, indicating that a memory limit has been exceeded, monitoring a process and indicating faults.

The LEDs can be switched in the command line application piTest with the variable RevPiLED.

The RevPiLED output has a defined byte length and therefore has a certain number of bits that are read from right to left. Certain bit positions are each assigned to an LED. The LED is switched by setting the respective bits to 0 or 1.

| LED | Assigned bit position |

|---|---|

| A1 | 0 and 1 |

| A2 | 2 and 3 |

An LED signal is set in the command line with the command piTest -w RevPiLED,x where x corresponds to the decimal value calculated from the respective bit pattern.

| LED | Signal | Bit pattern | Decimal value |

|---|---|---|---|

| A1 – A2 | off | 0000 | 0 |

| A1 | green | 0001 | 1 |

| red | 0010 | 2 | |

| orange | 0011 | 3 | |

| A2 | green | 0100 | 4 |

| red | 1000 | 8 | |

| orange | 1100 | 12 |

To switch several LEDs simultaneously, the respective decimal values have to be added up.

Example: If LED A1 shall flash red and LED A2 green at the same time, the command is piTest -w RevPiLED,6 (bit pattern: 0000 0110 = decimal values 2+4).

If a signal is to be added to an existing LED circuit, the value for all required signals must be recalculated and rewritten.